Looking for a sensor for tight spaces? Try the separated mini inductive one!

What is a Mini Inductive Sensor?

Understanding inductive proximity sensors

Inductive proximity sensors are non-contact devices designed to detect metallic objects without making physical contact. Operating on the principle of electromagnetic induction, these sensors generate an electromagnetic field to identify targets. They are widely used in industrial settings for automation and safety due to their ability to reduce wear and tear by avoiding physical contact. Their effectiveness and reliability make them essential in many modern production environments.

How mini inductive sensors differ from standard sensors

Mini inductive sensors are notably smaller in size compared to their standard counterparts, making them ideal for applications where space is limited, such as in tight spaces or compact machinery. Despite their reduced size, these mini sensors maintain high detection accuracy and often feature similar or even enhanced performance metrics. Their compact form factor allows them to be integrated into challenging environments without sacrificing functionality, providing efficient sensing solutions in limited spaces.

Benefits of Mini Inductive Sensors in Tight Spaces

Enhanced detection accuracy in confined areas

Mini inductive sensors offer precise detection even in narrow or restricted spaces, making them invaluable in tight environments. Their compact size allows for closer proximity to the target, significantly improving accuracy. This makes them ideal for applications where precision is critical, such as robotic arms or small assembly lines, where maintaining exact positioning is essential.

Compact design for space-saving integration

The small footprint of mini inductive sensors makes them perfect for integration into tight spaces. These sensors can be installed in areas where standard-sized sensors might not fit, optimizing space utilization in machinery and equipment. Their compact design ensures that even complex systems can maintain functionality without compromising on efficiency or precision.

Robust performance in demanding environments

Mini inductive sensors are engineered to withstand harsh conditions, including high temperatures and vibrations. They offer reliable performance in industrial environments, contributing to minimal downtime and optimal productivity. This robustness makes them suitable for use in challenging sectors such as automotive and manufacturing, where resilience to environmental stressors is critical for continuous operation.

Proximity sensors like these, including the inductive proximity sensor, provide non-contact feedback, which is not only essential for safety in automation but also minimizes wear and tear, extending the lifespan of machinery components. By fitting seamlessly into compact spaces, these sensors ensure both high performance and efficient use of space.

Applications of Mini Inductive Sensors

Industrial Automation and Robotic Arms

Mini inductive sensors are indispensable in industrial automation, providing precise object detection. They play a crucial role in robotic arms by ensuring accurate positioning and seamless movement. These sensors enhance efficiencies and contribute to minimal errors in automated processes, such as assembly lines and task execution, making them a cornerstone in advanced manufacturing settings.

Conveyor Systems for Material Handling

Mini inductive sensors are essential in conveyor systems for detecting the presence or absence of items, ensuring smooth material handling. By preventing jams and misalignments, these sensors support uninterrupted operation. They are ideal for logistics, packaging, and manufacturing industries, where operations often depend on the efficient flow of materials along conveyors.

Automotive Industry for Component Detection

In the automotive sector, mini inductive sensors play a vital role in component detection during the assembly process. They ensure precise placement of parts, thereby improving the overall quality and reliability of vehicles. These sensors are commonly employed in critical areas like engine assembly and brake systems, providing accuracy that is essential for maintaining high standards in vehicle manufacturing.

Key Features to Look for in Mini Inductive Sensors

High Detection Accuracy

When selecting a mini inductive sensor, it is vital to prioritize sensors that offer high detection accuracy. Accurate sensors are crucial for applications requiring precision, such as manufacturing and automated systems. They ensure reliable performance, reduce errors, and aid in maintaining the quality of production processes. It is advisable to review the sensor's specifications, especially focusing on key attributes like repeatability and sensing distance, to ensure they meet your application's demands.

Wide Operating Temperature Range

Opt for sensors that can function effectively across a wide range of temperatures. This feature provides versatility, allowing sensors to operate in challenging environments, including those with extreme thermal conditions such as foundries or outdoor installations. Ensuring that your sensor maintains optimal performance under varying temperatures is crucial for reliability. Therefore, evaluating the operating temperature range in the specifications is essential to safeguard continuous and effective operation.

Easy Installation and Maintenance

Choose mini inductive sensors that offer easy installation and minimal maintenance to streamline setup and reduce downtime. Features like plug-and-play connectivity are beneficial as they simplify integration into existing systems. Moreover, sensors with durable housing can withstand harsh conditions, further minimizing the need for frequent maintenance. This ease of use not only lowers long-term operational costs but also enhances efficiency by minimizing interruptions in the workflow.

Top Mini Inductive Sensors for Tight Spaces

Q5 Square Inductive Sensor

The Q5 square inductive sensor is renowned for its compact design and high-performance capabilities, making it an excellent choice for applications requiring precise and reliable detection. Its robust housing allows it to function effectively in demanding environments, while its small footprint makes it ideal for tight spaces. This sensor is widely used in industrial automation, packaging, and automotive applications where space-saving integration is crucial.

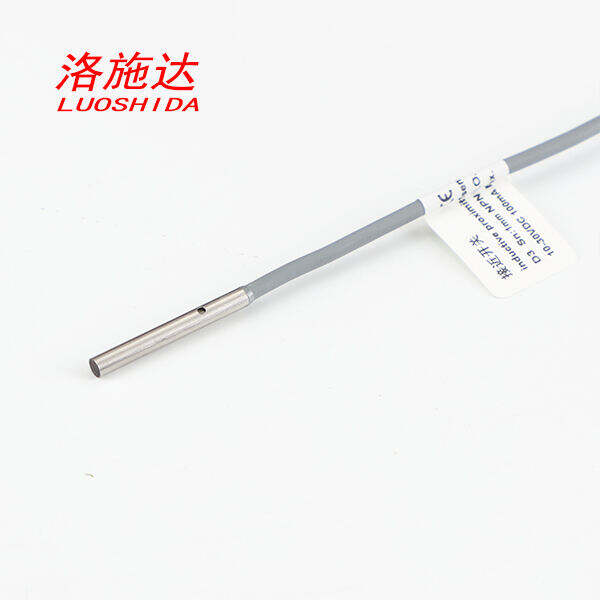

D3 Mini Inductive Sensor with Cable Type

The D3 mini inductive sensor excels in tight and confined spaces due to its flexible cable-type design, which allows for straightforward installation and reliable electrical connectivity. It provides high sensitivity and consistent detection, making it suitable for automation tasks and material handling systems. This mini sensor's durability and ease of use make it an effective solution for optimizing operational efficiency in various industrial applications.

How to Choose the Right Mini Inductive Sensor

Consider the sensing distance

The sensing distance is a critical factor when selecting a mini inductive sensor. Determine the precise distance required for your specific application to choose a sensor that ensures accurate detection. A sensor with a matching range will enhance functionality, while longer sensing distances may be necessary for larger or more complex systems. This ensures efficient and reliable performance tailored to the conditions of your use case.

Evaluate the housing material

Selecting the right housing material is essential for the sensor's durability and performance. Choose a material that suits your environment, such as stainless steel, plastic, or nickel-plated brass. Each option offers different levels of durability and resistance to environmental conditions. Durable housing materials not only ensure the longevity of the sensor but also protect against wear and tear, which is particularly important in demanding industrial settings.

Check for compatibility with your system

Compatibility with existing systems or machinery is vital to avoid integration challenges. Before selecting a sensor, verify voltage requirements, output types, and connectivity options to ensure seamless operation. This proactive approach reduces potential issues during installation and helps integrate the sensor smoothly, promoting efficient system functionality and reliable performance in your applications.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES