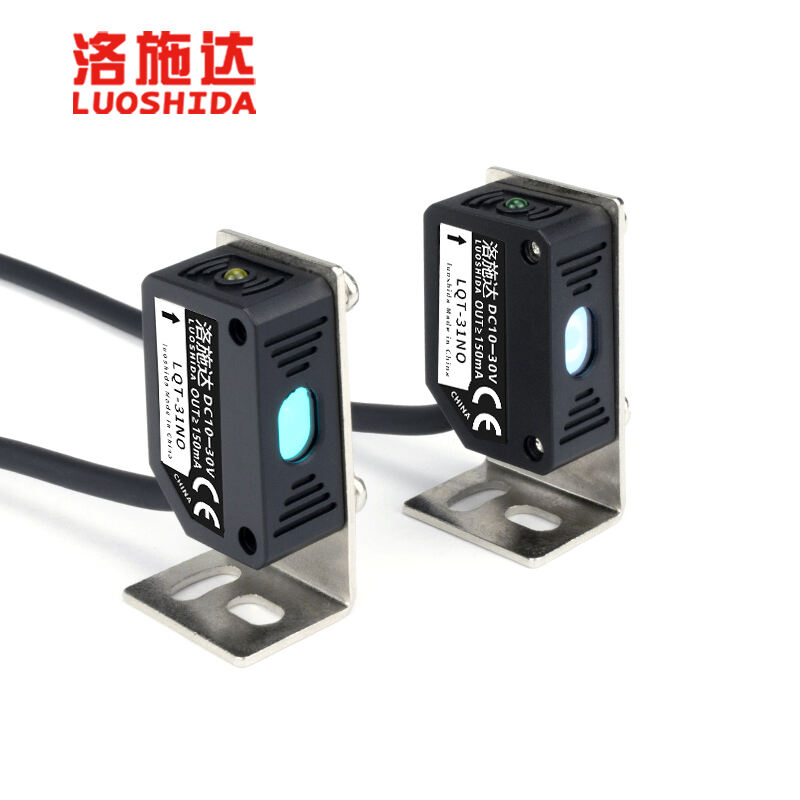

Handling materials accurately and moving them in a systematic manner is one of the vital elements of any manufacturing or a distribution system. Material and component detection is paramount to constant process optimization, fewer mistakes, and increased productivity. LUOSHIDA laser sensors are essential in modifying the material handling systems because they help with object measuring and detection and movement control.

Material lasers and their impact on the industry

Material handling systems demand movement of objects in the most desired fashion, this is where lasers are pivotal in ensuring the desired piece is moved in its required placement. LUOSHIDA laser systems provide an alternative that is fast and does not require contact to track shift in components or pieces ensuring that no asset is skipped when processing.

How LUOSHIDA laser sensors have aided in material handling

Speedy Scanning: LUOSHIDA laser sensors are designed for speed thus making their use in measuring distances seamless and convenient. Which when systemized improves efficiency in the mechanics of handling materials.

Non-Invasive Techniques: This feature is usually an added advantage when using laser sensors for material handling since it allows for measurements without interfering with the object, however, a laser sensor problem will not result in replacement of the object.

Enhanced Precision: As a result of LUOSHIDA’s laser sensor’s specificity, identification, sorting and tracking of materials while they are in motion along conveyor belts or any other means of transportation is correct.

Versatile Applications: LUOSHIDA’s laser sensors may come in handy for any material handling, such as checking for package dimensions, checking for the number of items available, and placing the items on pallets.

Reduced Maintenance Costs: Because of their non-contact format and sturdy design, LUOSHIDA’s laser sensors are low maintenance compared to traditional sensors which contact each other; this means they cost less to operate and have short non-usage periods.

Applications in Material Handling

Object Detection: This technique follows on from the previous one whereby laser sensors follow materials which are moving through conveyor belts in order to determine the type and sort of material they are dealing with.

Inventory Tracking: LUOSHIDA’s laser sensors are also able to check inventory levels in warehouses or any other storage spaces and make sure the materials in question are well counted and recorded.

Positioning: Laser positioning can also be used in this sense to make sure that materials are placed on pallets in an automated storage system properly and this reduces the chances of making errors.

Conclusion

LUOSHIDA laser sensors aid in rapidly identifying materials in a non-contact way. They have the ability to be used in all areas of a business due to their accuracy and speed which would improve the material handling process in all the sectors reducing errors and improving efficiency at a cost effective price.