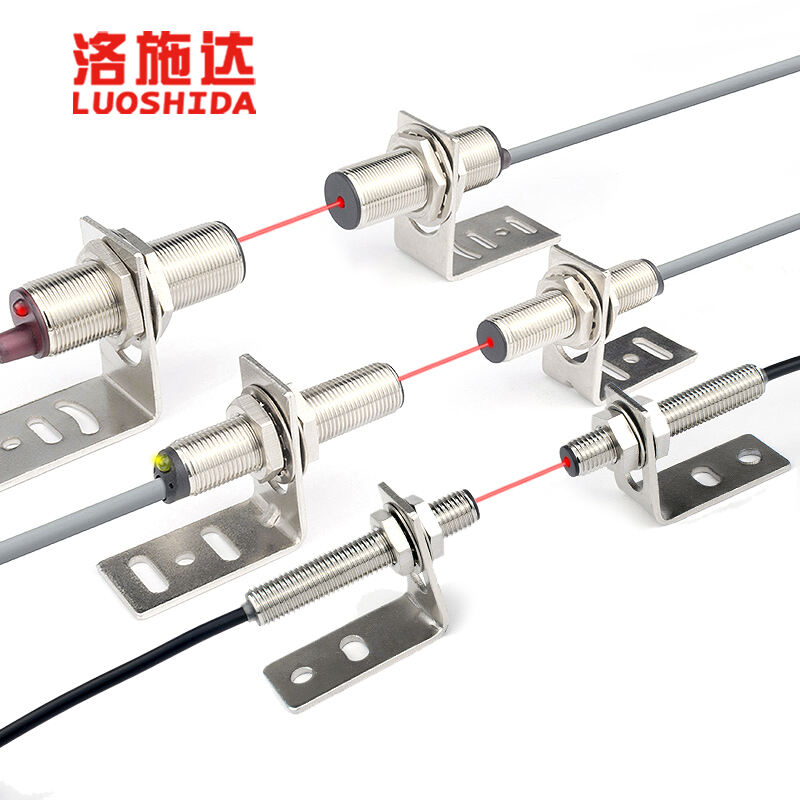

As more companies turn towards the automation of their industrial processes, the systems of measurement become even harder to develop than before. LUOSHIDA, one of the leaders in sensor technology, introduces an impressive line of laser sensors with enhanced object detection and distance measuring functionality.

The Role of Laser Sensors in Modern Industry

The laser sensor is based on a very simple, but efficient concept; a laser sensor fires a laser beam at an object and afterwards measures the time it takes for the reflected laser beam to return in order to calculate the distance. This method is beneficial to industries as it is not contact based, therefore it is efficient and can be employed across various applications.

The automation of industrial processes results in various demands for enhancement. LUOSHIDA sensors are able to meet these challenges with ease, whether it’s for detection of an object from an assembly line or taking important measurements.

Key Features of LUOSHIDA Laser Sensors

One of the few things that limits LUOSHIDA Laser Sensors is the environment in which they are used. Aside from that, the laser sensors are able to showcase their accuracy in taking measurements even under challenging conditions and demanding applications.

Durability: LUOSHIDA laser sensors can withstand harsh environments, extreme temperatures, humidity, and even dust, making them highly durable. Their robust nature makes them suitable for the automotive, packaging, and heavy manufacturing sectors.

Fast Response Time: It's all about speed with LUOSHIDA laser sensors as detection is achieved instantaneously. This caters for the quick measurement of changes making it easier for businesses to minimize downtimes while making systems more efficient in their response to changes.

Wide Application Range: Usability of these sensors is not limited, they can be utilized in robotics, conveyor systems, industrial automation and even logistics. In addition, being able to detect objects, measure distance or change in position of certain components makes them helpful across any industry.

LUOSHIDA Laser Sensors Applications

Industrial Automation: A lot of process automation in the automotive and electronics industries are made possible by the integration of LUOSHIDA laser sensors into robotic systems. Incorporating sensors minimises the chances of mistakes on assembly lines by ensuring that movements are precise.

Packaging and Sorting: Robotics systems have made LUOSHIDA laser sensors an important tool in the packing sector, helping in the sorting and detection of items. These laser sensors not only sort out items but can also give information concerning the orientation and position of objects thus ensuring they are appropriately packed without any manual work.

In warehouses and distribution centers, laser sensors enhance the workflow by scanning for items mounted on automated storage systems and conveyor belts.

A laser sensor finds a place in safety systems as well. These devices can detect dangers and obstacles in danger zones and prevent a mishap from occurring in an environment wherein safety is of utmost concern.

What Makes LUOSHIDA Laser Sensors More Performs Than Others

LUOSHIDA’s sensors possess laser and are accurate, extremely reliable and durable to fulfill the demands of today’s standard. The measuring is non contact and the effectiveness level achieved is among the best which makes it most appealing to the businesses. Selection of LUOSHIDA would help the companies in achieving better productivity, reduced cost on maintenance and enhancement of quality of products.