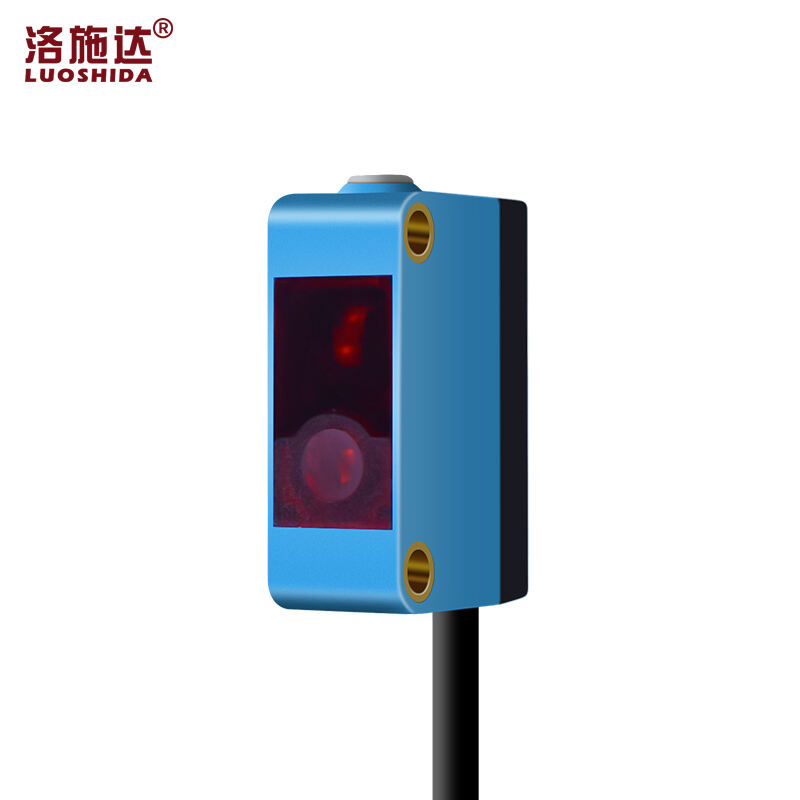

An important consideration in any manufacturing or distribution setting is the ability to manage, organize and transport materials and components with high accuracy. This combined with laser and component recognition leads to process improvement, reduced errors and increased productivity. LUOSHIDA laser sensors are indispensable in the automation of the material handling processes as they assist in the measurement and assessment of objects as well as in control of movement.

Lasers for material preparations and their implications for the business

For material dissemination operations, transitioning materials into other forms of materials is important and this is where LUOSHIDA laser systems comes in to effect where tracking of components through lasering is employed to ensure no pizza is left outside the oven. Movement of materials has been of particular interest to the handling of laser and for LUOSHIDA laser systems this is not an exception.

What allows LUOSHIDA laser sensors to work in the material handling processes.

Fast Scanners: Most material handling needs lasers for precision and accurate measurements but since LUOSHIDA laser sensors are fast secured distances the task at hand becomes simple. Which when systemized improves efficiency in the mechanics of handling materials.

Non-Intrusive Methods: This attribute is mostly an additional advantage in the use of laser sensors for material handling as it allows one to take measurements without touching the object, however, if there is a malfunction in the laser sensor, then there is no need to exchange the object.

Improved Accuracy: LUOSHIDA’s laser sensor being particular, facilitates the accurate identification, classification and tracking of materials even when the materials are in motion on the conveyor or any means of transportation.

Wide Range Of Uses: LUOSHIDA’s laser sensors might prove to be effective in any material handling for example determining the size of a package, ascertaining how many items exist or positioning the items on the pallets.

Lower Cost of Servicing: The low maintenance is attributed to their non-contact format and robust construction which is well designed, LUOSHIDA’s laser sensors are lower maintenance than traditional sensors which are in contact with each other, which implies that they are cheaper to run and have brief downtime.

Uses in Material Handling Systems

Object tracking: This method moves from the previous one in which it tracks objects that are transported on conveyor belts with laser sensors in order to identify what type and which class of material they are using.

Inventory Tracking: Warehouse’s inventory levels can be checked using LUOSHIDA’s laser sensors in such a way if the materials are counted hence they are recorded.

Positioning: Laser positioning can also be used in this sense so that materials placed on the pallets in automated storages systems are placed exactly and the chances of making errors are reduced.

Conclusion

LUOSHIDA laser sensors make it easier to find materials in a contactless way and have the potential to fit across the business in all areas because of their precision and speed that would enhance the material handling processes in all the sectors, lowering errors and improving effectiveness at a more reasonable cost.