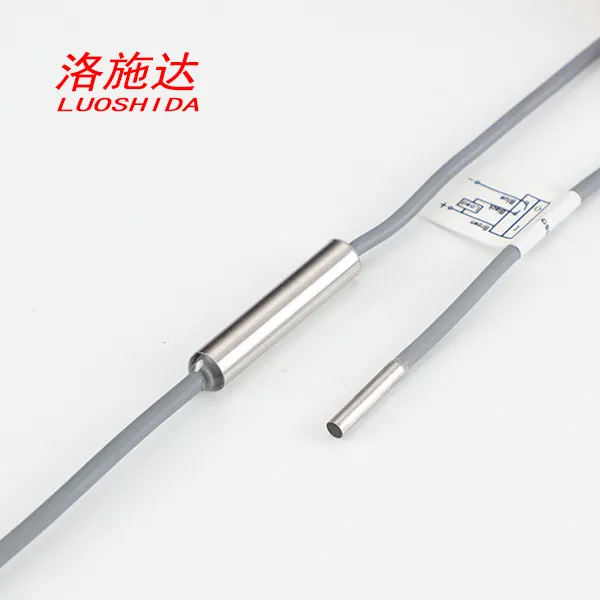

Inductive Proximity Sensors from LUOSHIDA: Efficient and Non-Contact Detection for Metal Objects

However, in the recent years LUOSHIDA, a sensor technology company which has risen among the ranks, has ensured an efficient solution – the Inductive Proximity Sensors - which detect metal objects without the need for contact; therefore, eliminating unnecessary material collisions while maintaining precision and reliability. Inductive proximity sensors cut to the chase as they’re easy to install and integrate. These sensors are frequently utilized to ascertain whether metallic items are present or not, while maintaining contact-free scanning in even the most challenging working conditions.

What are Inductive Proximity Sensors?

So basically, these sensors enable people to establish whether metal items are within the range of the electrode to which the sensor is attached without having to touch them. As a result, it is built around an electromagnetic field and when metal penetrates near the sensing range, this field is disrupted and the sensor detects the disturbance and reacts. Certain problems have been solved thanks to Inductive Proximity Sensors, improving both the effectiveness and efficiency of industrial processes. For those in the manufacturing, automotive, or robotic industries inductive proximity sensors built by LUOSHIDA could be the right solution.

Guard points of LUOSHIDA Inductive Proximity Sensors

Particularly prominent are the LUOSHIDA inductive proximity sensors nos-interference detection thanks to their non-contact operation which reduces the wear and tear of these sensors. These sensors are quite robust and function across harsh conditions such as high temperatures, humidity, and vibration which guarantees survivability in industrial application. Besides, LUOSHIDA sensing devices exploit modern techniques of high accuracy and sensitivity which ensures detection of very small metal pieces.

Use of inductive sensors into automated systems: areas of use

Inductive proximity sensors designed by LUOSHIDA have broad application and can be used in various industries. In automation systems, they are mostly used for position detection, counting, and safety. As an example, in the automobile industry, these sensors can be utilized in ascertaining the position of mechanized components along an assembly line. In industries, they help control the correct position of the working equipment and its state. With LUOSHIDA senors, processes of production are enhanced through increased accuracy, reduced errors, and enhanced efficiency.

What Makes LUOSHIDA Sensors Unique?

In the sensor business, LUOSHIDA is known for its dedication to uniqueness and breakthrough development. More specifically, their inductive proximity sensors have the capabilities to last reasonably well in harsh situations for a number of years. With the technological advancement and satisfaction within the industry, LUOSHIDA’s sensors are guaranteed to adhere to the strictest and highest standards in the entire industry. The company has several models, all of which have been carefully crafted for specific uses, thereby providing customers with dependable and affordable alternatives for locating metallic objects.

In conclusion, LUOSHIDA’s inductive proximity sensors have made a name for themselves as very useful in industry due to their ability to detect metal objects without direct contact. With their robust design, high accuracy and versatility; these sensors can work in a range of applications. Whether you are in need of increasing the level of automation of certain processes, increasing operational safety or increasing productivity, this is where LUOSHIDA’s inductive proximity sensors strive to promise.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES