A distinctive feature of the capacitive dielectric proximity sensor is the coexistence of many unique lines, absolute resolution of the boundaries which by its design capacity operates on multiple frequencies and while able to cope single handedly to normal interference external ranging. Thus, it becomes necessary to know how to fix problems because these are the daily challenges posed by devices that make use of sensors or in this case, capacitive proximity sensors.

Common problems encountered in the operation of capacitive proximity sensors include the following ones Electromagnetic Interference: is one of the issues that is widely related in the use of capacitive proximity sensors, the electromagnetic interference is more common when the sensor gets hit systematically with a magnetic field or with an electrical signal from another impenetrable heavily shielded object.

Is there a way to fix this? Assess where the excessive current may be coming from or check if there are electronic devices located in vectors surrounding the sensor, as well as mess wiring to the sensor. It is also good practice to follow the instructions given by the manufacturer of the sensor fitted in the manual.

Lower Resolution values: There is a noticeable pattern over the years that indicates a capacitor sets the value of its sensor at a lower level, or else it loses a definite measure for the region which it can cover itself. The surfaces of capacitive sensors get moist and are contaminated by particles of dust getting on to the sensor surfaces. Therefore, the capacitive sensors are very time sensitive and prone to risks where they completely fail to read or perform actions through sensing objects.

How to remedy the situation: Make sure that the angle or position of a sensor is accurate and that no objects would come ten inches close to the sensor. A sensor should be regularly cleaned with a dry cloth so that it is out of mole and well rounded dust particles that have been obtained. Lastly make sure that the sensor is made in line with the specifications as earlier stated.

Inconsistent detection: The mounting of capacitive proximity sensors may cause inconsistent detection phenomena if the device is placed too near to a big mass of metal or any other material that interferes with or modifies the vicinity of the detection field of the sensor.

Answer: Llike we spoke about earlier, the user in the beginning can adjust or set up the detection range of the sensor so that it fits the application. Further, ensure that the sensor is set some distance away from large metallic mass so that its field is not interfered with as well.

How Capacitive Proximity Sensors Work to Fix These Problems

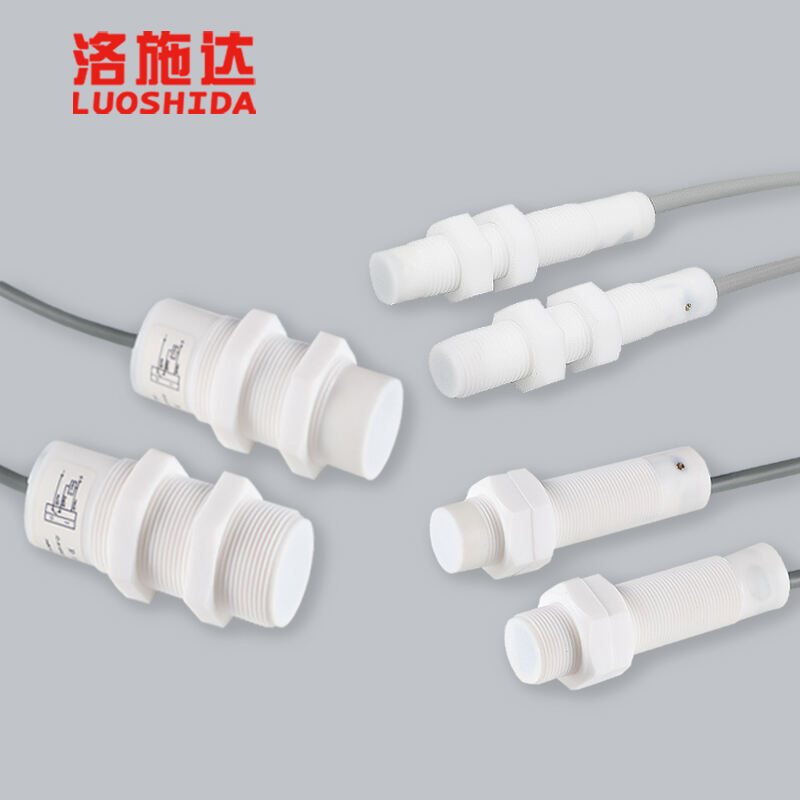

LUOSHIDA capacitive proximity sensors are designed to handle quite a lot of punishment and are expected to perform brilliantly under very harsh conditions. They are made from high grade materials with the highest level of precision engineering that assures clear and strong performance of the sensors even in difficult conditions. Correct installation procedures and routine maintenance are essential in ensuring that the sensors are reliable and have a long operational life.