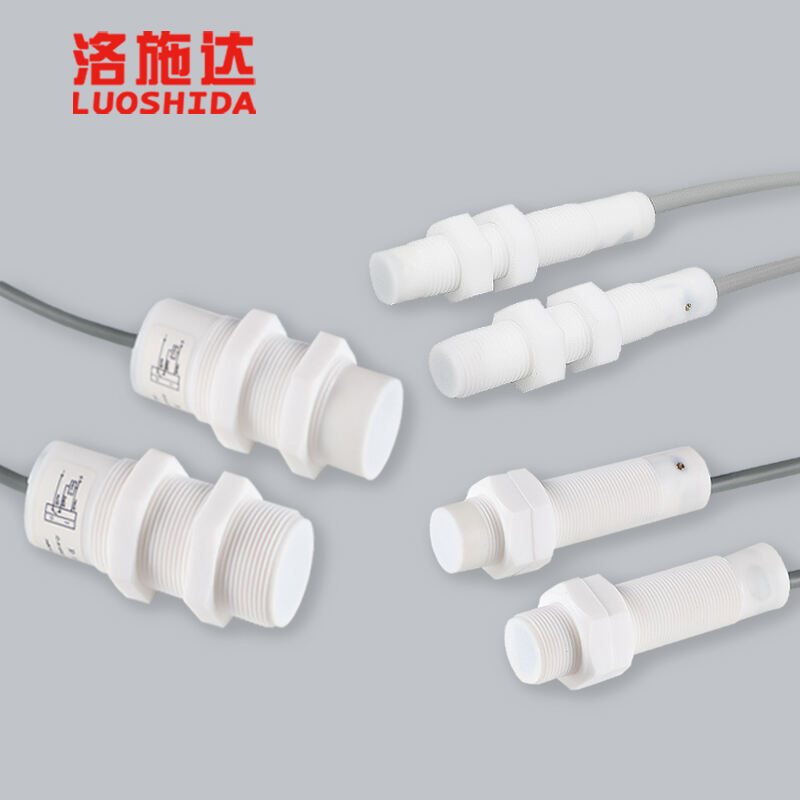

In the manufacturing processes of modern factories, there is no room for physical contact, thanks to technologies such as capacitive proximity sensors. These sensors work even with the change in the constants of matter using the concept of capacitance. As a versatile use for liquid detection and in automation systems, these sensors find great significance in a variety of fields. LUOSHIDA is one of the companies working on this technology and they manufacture impressive sensors such as capacitive proximity sensors which are accurate and can cater additional industrial applications.

How it Works: Capacitive Proximity Sensors

Based on the concept of capacitance, a capacitive proximity sensor functions. First it emits an electric field of sorts and then objects within its proximity are able to interact with it. For instance, if a hand is placed within the proximity of the sensor and moved, the electric field will be affected. When an object comes close to a sensor, some portions of the electric field will be disturbed, hence changes the area’s capacitance. This change is captured by a circuit built inside the sensor and creates an active output from the flow of change and converts to a non-active output.

The noticeable distinction of the capacitive proximity sensors in comparison to others is their capability of picking up even non-metal bidders, non-metal liquefied form, plastics and granular materials and this makes them applicable for use in any industrial activities that necessitates non-contact detection.

Key Benefits of Capacitive Proximity Sensors

No physical contact necessary: The most important point of a capacitive sensor is that no contact is made with the target and this aspect enhances the extent of wear and tear thus lengthening the lifespan of the sensor and the target being sensed.

Sensitive Measurement: The capacitive proximity sensor is capable of measuring both metallic and non-metallic materials and as such, it is quite powerful and can be used across many industries in the industrial sector.

Resistant to Harsh Conditions: The design concepts for capacitive sensors has taken high temperature, moisture and dirt into consideration making it hard for others to do so and thus making harsh industrial settings the perfect environment for such sensors.

Applications of LUOSHIDA Capacitive Proximity Sensors

Capacitive sensors are integrated in assembly lines to detect objects such as bodies and granules in the presence of any such work including: Automated Manufacturing: In such work, the sensors detect whether an object is on conveyor belts or in a robotic arm which enhances the precision in controlling the assembly lines or production processes.

Food and Beverage: Food packaging systems incorporate capacitive sensors to solve the problem of maintaining standards for the amount of liquid or powder to be added in the package.

Material Handling: The well positioned capacitive proximity sensors strategically placed in warehouses or logistics centers assists the movement of goods leading to better inventory management.