Every system involved in the aerospace industry such as management structures, protocols, and equipment is required to maintain maximum precision, optimal performance, and the highest levels of safety. In addition, the fiber optic sensors designed and manufactured by LUOSHIDA offer advanced and unique solutions to the complex requirements specific to the aerospace needs. The fiber optic sensors developed by LUOSHIDA stand out as a top tier solution to the demands of the aerospace industry. This article will explain why fiber optic sensors are the most crucial component in aerospace applications. Furthermore, LUOSHIDA has established itself as the dominant force in providing and developing critical components for the aerospace industry, such applications include accurate and dependable sensors.

The importance of Sensors in Aviation

Sensors play an important part in aerospace applications as they monitor the important systems including propulsion, fuel systems and surrounding atmosphere. Moreover, optimal safety, efficiency, and effective performance are heavily reliant on the precise and accurate data collected by the sensors. As the aerospace operating environment is very harsh, fiber optic sensors are ideal due to their accurate performance in extreme conditions.

Benefits of Using Fiber Optic Sensors in Aerospace

For the aerospace industry, LUOSHIDA fiber optic sensors are well suited for they are high precision as well as they are very accurate which is needed because even the slightest mismatch in the measurements could result in dire consequences for the aerospace systems. Fiber optic sensors are also perfect for aerospace applications because they are not affected by electrical currents, which is one of the most significant advantages they have over traditional sensors.

Extreme Harshness Makes Aerospace Environment And LUOSHIDA Fiber Optic Sensors Stand Tough - LUOSHIDA fiber optic sensors are constructed to bear weather extremes of temperature, pressure and even stimulation given the long critical lapse missions require. These sensors remain unaffected by the extreme harshness of weather and enable long lasting reliability.

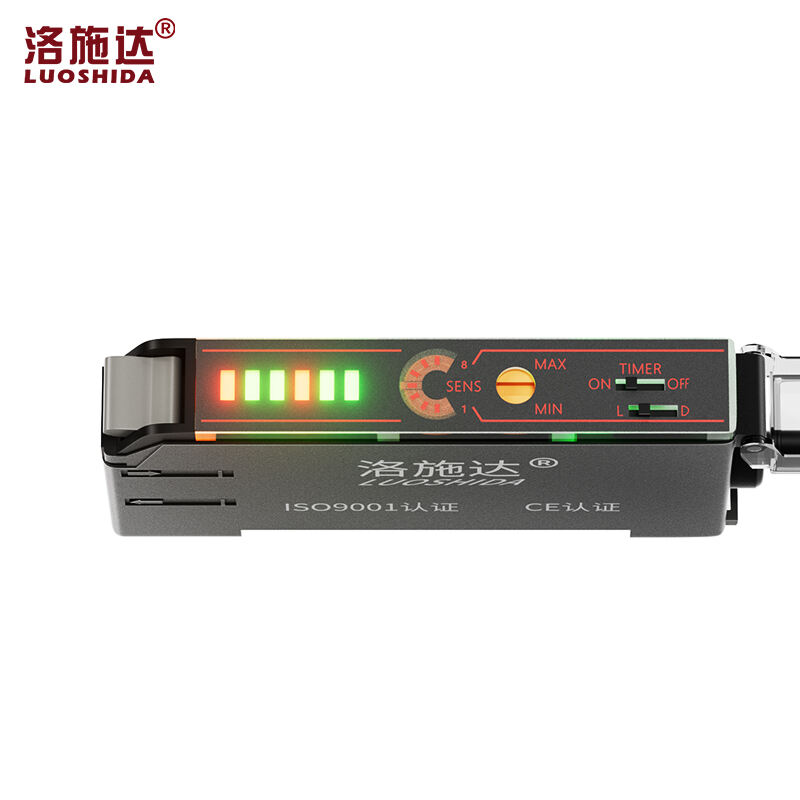

Light And Easy to Use - LUOSHIDA fiber optic sensors are of light weight and small dimensions thus making them suitable for use in aerospace systems where it is required to trim down the total overall weight of the system.

Due to different properties and working of fiber optic sensors it is being utilized for various aerospace functions.

Aerospace Flight Control Systems: These systems are monitored for proper functional performance of all controls fitted on a plane.

Fuel and Engine Due to requirements of air planes, it is vital to monitor air pressure and fuel in real-time as well as manage the engine in a secure manner.

Place On Aircraft Anytime and Anywhere: Climate range, pressure and vibrations of an area on a plant can be measured using fiber optic sensors.

It is quite evident from the functionalities that LUOSHIDA fiber optic sensors can easily fit into aerospace environment and additionally LUOSHIDA has ensured that their sensors are integrated with latest technologies and information support best practices related to aerospace integrators. They are focused on meeting the requirements of the aerospace sector through providing necessary reliability, precision and appropriate deliverables which are crucial in the industry.