El mundo de la automatización industrial sigue en desarrollo, a medida que avanza la necesidad de contar con tecnologías más avanzadas y precisas. Una de estas innovaciones que ha demostrado ser un cambio entre varias industrias es el sensor de fibra óptica. Estos sensores son capaces de localizar algún cambio en su entorno mediante el uso de luz, lo cual los hace tener ciertas ventajas respecto a los sensores tradicionales. En este artículo intentaremos desmitify the role of LUOSHIDA fiber optic sensors in automation enhancement, their importance and how they help improving the performance of operations.

Some Key Terms Related To Fiber Optic Sensors

The principle goal of a fiber optic sensor is to detect specific characteristics of the sensor’s light in order to measure a certain physical condition. For instance, a strain optic cable sensor detects tension in a certain part by measuring the optical transmission through the cable. Such sensors provide a means of sensing that is not electrically powered and, therefore, does not suffer from EMI problems that are very common in many applications.

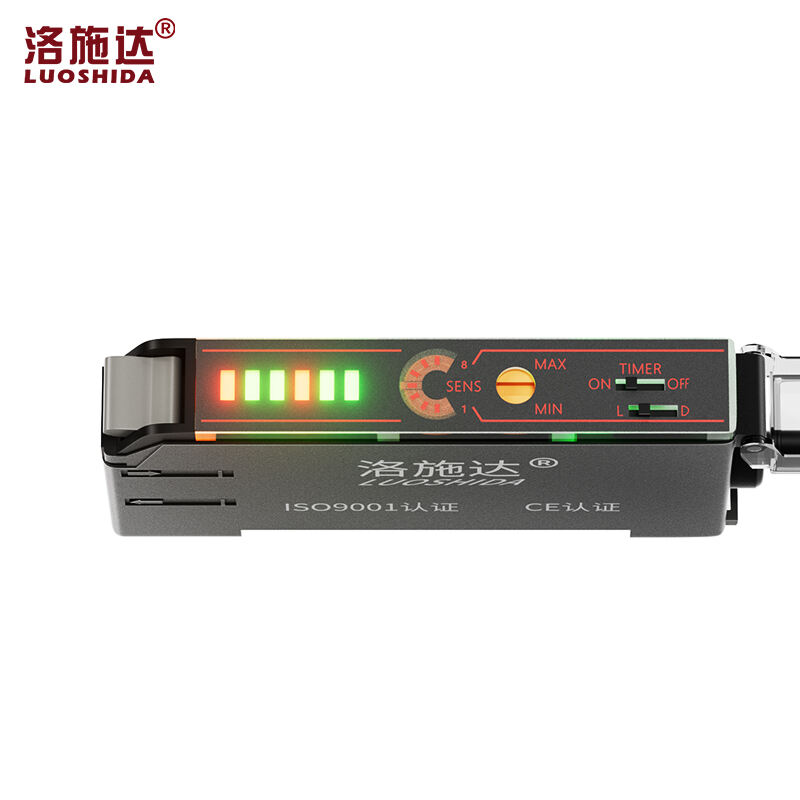

What Are the LUOSHIDA Fiber Optic Sensors Notable Features?

LUOSHIDA, one of the known industrial sensing solutions provider deals with a variety of products including fiber optic sensors suited for areas such as automation, manufacturing and robotics. Loushida’s solution is a known market leader due to the vast improvements it brings in reliability, durability, and precision. With the rugged construction, the sensors are practically immune to any electrical noise, which perfectly suits the needs of power generation establishments, factories and high precision measuring machines.

Advantage Of Fiber Optic Sensors In Automation

Electromagnetic Interference Free Operation

With almost all electrical components, machinery and devices being a source of electromagnetic fields, a major hurdle for traditional sensors is getting affected which affects the machine performance. A major drawback to that is overcome by LUOSHIDA’s fiber optic sensors which remain immune to Electromagnetic Interference (EMI). This ensures seamless operations in highly electrified environments without any discrepancies.

High Sensitivity And Accuracy

In fields of applications whereby minute changes have a cascading effect on system performance, such as environmental conditions LUOSHIDA’s fiber optic sensor provide adequate support, due to their exceptional sensitivity and precision level. Further on, various applications such as temperature or pressure control and strain measurement ends up becoming automated due to the accurate sensor performance provided by Loushida.

Efficient Design for Seamless Integration

The LUOSHIDA fiber optic sensors are small and flexible which makes the sensors easily adaptable to already existing systems. They can be employed in small gaps or be mounted in locations that with the use of traditional sensors are hard to reach. Because of these reasons, they are suitable for use in industrial automation systems where precise measurements are an absolute necessity, yet only a small footprint is available.

Robustness in Demanding Conditions

The industrial world is characterized by severe temperatures, harsh chemical exposures and high pressure all of which can be a problem. However, LUOSHIDA fiber optic sensors have been crafted to endure such conditions, allowing the sensors to operate in scenarios that would be otherwise impossible for other sensors. LUOSHIDA’s fiber optic sensors are durable due to their long-lasting efficiency and lower maintenance costs, making them well worth the money in industries like automotive, aerospace and food production.

Uses of LUOSHIDA Fiber Optic Sensors

Multiple industries utilize LUOSHIDA’s fiber optic sensors in a range its applications for instance;

Automation and Control Systems: LUOSHIDA’s fiber optic sensors are extensively used in automated systems and machinery to check the temperature, pressure or displacement of structures or areas.

Robotics: It is critical for sensors to be accurate in motion control for robotic systems. LUOSHIDA’s fiber optic sensors provide accurate feedback on component positioning and movement eliminating mechanical jerks.

Energy Production: The oil and gas, or power, sector gets constant monitoring of pipelines, reactors, and other critical systems with fiber optic sensors.

Environmental Monitoring: LUOSHIDA fiber optic sensors are simply the best for environmental monitoring since they provide real-time transmission of air quality, temperature and capabilities.