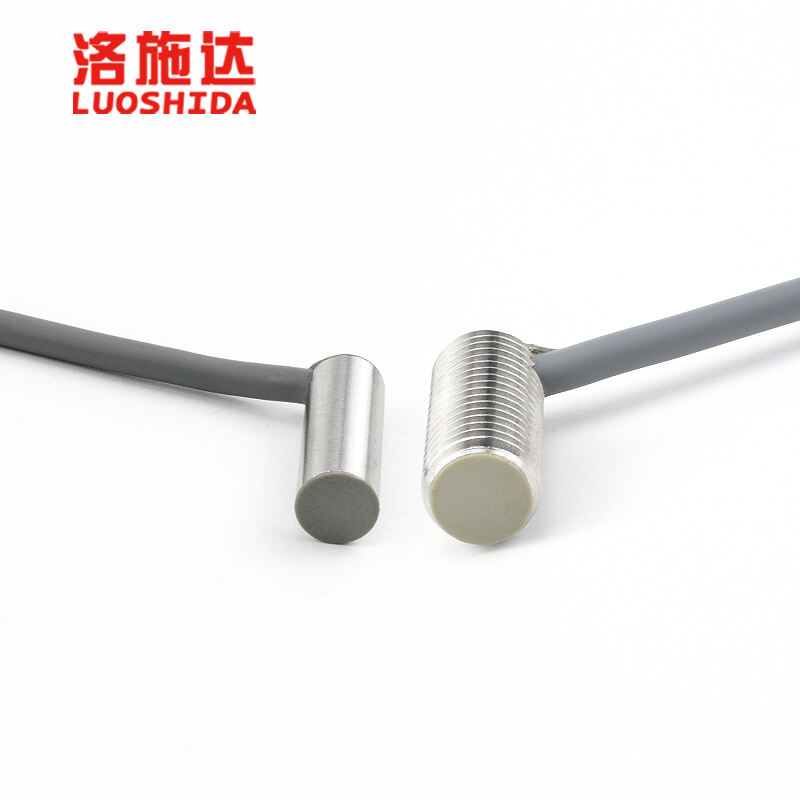

In addition to high temperatures and vibration, moisture and dust are industrial environment’s norm. These conditions are suitable for the gradual damage of ordinary mechanical sensors. This problem is resolved through LUOSHIDA’s inductive proximity sensors which are specially designed and offer dependability in such conditions.

Inductive Sensors vs. Conventional Mechanical Sensors

Due to direct contact with the items, conventional mechanical sensors are also exposed to the likelihood of sustaining damage. However, this is not the case for inductive proximity sensors since they are non-contact devices, therefore there is no risk of sustaining mechanical damage. Moreover, they also do not suffer any damage due to dust, water, and in fact, even temperature variations.

LUOSHIDA’s inductive sensors are able to withstand dust and moisture with their strong, tough housing and seals. This capability enables LUOSHIDA’s inductive sensors to function across several applications in the industrial space, which includes food, automobile, fabrication, etc.

Applications in Harsh Environment

As contamination and cleanliness are critical in food production lines, LUOSHIDA’s inductive sensors are able to meet the industry’s hygiene requirements. Not only do they help in achieving compliance but they are also highly efficient in detecting metal objects which makes the sensor reliable.

Automotive Manufacturing: The automotive sector often has need for sensors that survive under extreme temperatures and vibrations. LUOSHIDA’s inductive proximity sensors prove to be the best in case of detecting metallic parts required in high speed assembly machines to ensure accurate placement and alignment on the assembly line.

Metalworking and Heavy Machinery: Inductive sensors in metal industry are used for monitoring the position of metallic components being placed and assembled in the rest of the processes. They are effective even when the amount of dust or metal shavings is excessive in the place of use.

Why Use LUOSHIDA’s Inductive Proximity Sensors?

LUOSHIDA’s inductive proximity sensors are made for tough conditions. The combination of their work in extreme conditions, high durability and accurate detection only continues to broaden their appeal among industries in need of trustworthy products. Inductive sensors also provide easy installation and maintenance which reduces the amount of time lost in production and lowers the operational cost.