With the more automation technology getting into industries, there is also improved efficiency from both the employees and the machines. Sanchez V and Courage H. Holosphere. S. R Engineering capacitive proximity sensors are also the demountable ventilation systems themsleves, so their significance can not be overemphasized. Thanks to the advancement in technology and globalisation, these sensors can be used in a number of applications because it has the ability to sense both metallic and non metallic objects.

The importance of Capacitive Proximity Sensors in Automation Systems

Industrial automation and industrial applications encompass a range of issues and can be applied and solved using one type of sensor, capacitive proximity sensor which is advantageous for industrial automation among many more sensors. They are very useful in situations where contact based sensors are not effective. The capacitive sensors have the ability to detect non metallic solids, liquids, or any other fragile substrates as they do not touch the object.

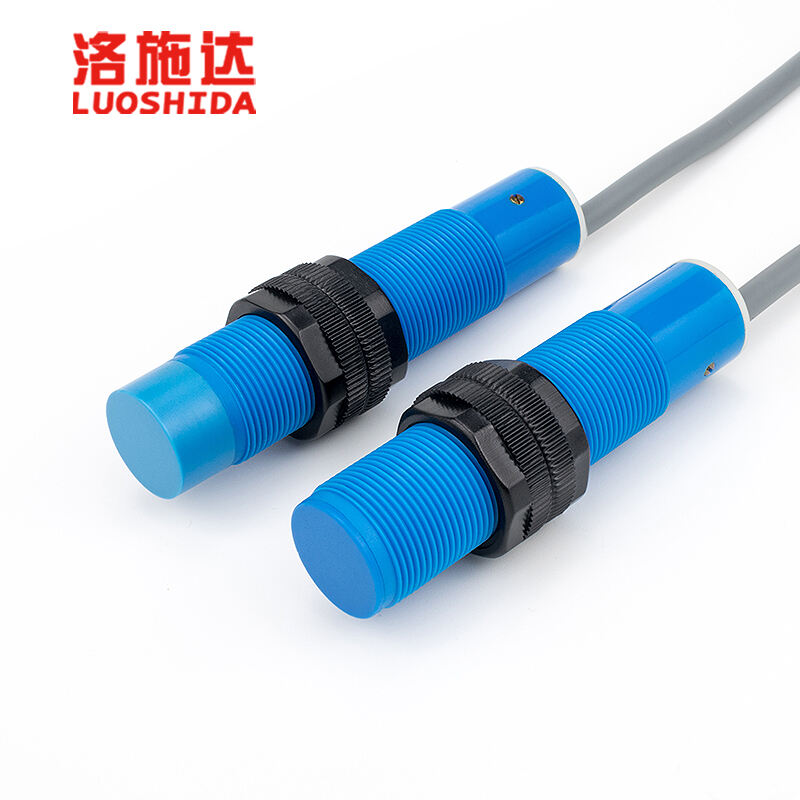

LUOSHIDA capacitive proximity sensors are a great option in various industries because they can detect liquid materials as well as light curtains.

The Main Benefits of LUOSHIDA’s Capacitive Proximity Sensors

Non-contact Sensing: Notice that capacitive sensors are composed of a capacitor which allows the sensor to interact with an object without necessarily making contact. In this way, the sensor and the object will experience minimal friction as well as minimal wear and tear which increases the lifespan of both devices.

Multi-material Detection: Alongside metals, the LUOSHIDA capacitive proximity sensors can also identify plastics, liquids and powders among others. Such versatility is crucial in industries that require the detection of materials of several types.

Resistance to Environmental Factors: LUOSHIDA’s capacitive proximity sensors are reliable for extreme temperatures, high humidity as well as dust particles since environmental factors do not affect operations of these sensors thus making them applicable in harsh industrial conditions.

High-Speed Performance: This is because of the fact that the sensors have quick responses enabling them to be utilized in high speed automated systems. The ability of these sensors to detect and respond to the presence of objects in a comparatively lesser time greatly improves the production lines and operational efficiency of the entire system.

Industries Benefiting from Capacitive Proximity Sensors

The capacitive proximity sensors are utilized in a variety of industries for a variety of needs.

Automotive: In the automotive industry, these sensors are utilized for object detection in robotic assembly lines increasing the accuracy and speed of production.

Pharmaceuticals: These sensors are in place to measure the amount of liquid that is utilized in the various processes of manufacturing drugs. This ensures that the required quantity of active ingredients are present in the drugs produced.

Packaging: Briefly, in automated packaging systems, embedded capacitive sensors are used for material identification and facilitate appropriate product sorting, counting, and placing within the packages while the appropriate sensors are sufficiently accurate for maintaining quality control.

You most probably will not regret investing in LUOSHIDA capacitive proximity sensors for your industrial machinery operations as they are most likely the best devices in terms of flexibility and reliability.