We live in an industrialized world that is constantly moving. Because of this, it is safe to say that photoelectric sensors are crucial components for the factories of today since safety comes hand in hand with efficiency, a goal that numerous companies seek to achieve through the sensors produced by LUOSHIDA. Automation can also be improved through the use of photoelectric sensors as they excel in their function of detecting items while remaining contactless, thereby increasing safety and productivity at the same time.

What Makes Photoelectric Sensors Ideal for Automation?

Photoelectric sensors are ideal for automation as they are great at detecting objects, regardless of the conditions for the sensors, and do so in a fast and reliable way. These sensors start to play an even bigger role when it comes to processes such as manufacturing, packaging and even quality control. This is due to the fact that these sensors require low – or none – contact and they allow for object detection which can be crucial for machines and even moving products or starting safety features.

The range of LUOSHIDA photoelectric sensors are suitable for various forms of industrial applications such as:

- Automated equipment or assembly lines where controllers require detection of small parts.

- Robotic systems that need to be positioned accurately and require distance measurement.

- Packaging systems that need to identifying if an object is present so that the system is able to handle the object in a controlled and quality manner.

Benefits of Industrial Photoelectric Sensors Technology

The automation industry has to figure out how to save time without cutting corners, and it all starts with LUOSHIDA photoelectric sensors, which advance technology by:

Automation of labor processes: Concentration and monitoring of processes are automated by using those sensors which decrease the role of man-power in production length of time.

Maximizing productivity: Continuous production process streams are made possible due to real time detection made possible by photoelectric sensors. This enables a reduction in waiting times and an increase in output in factories and storage areas.

Reducing wastage of resources: Efficient sensing of these sensors enables improvement in the performance of machinery so that only the required amount of power is used in operations.

Photoelectric Sensors in Control of Automation Processes

Real time operational safety across the automation processes is the other crucial necessity. To reduce hazards and risks, LUOSHIDA photoelectric sensors reduce the response time. They are good in:

Safety barriers: Safety management systems employ these sensors, which monitor if an operator is going into a hazard zone and stops the equipment to prevent an injury or accident.

Collision avoidance systems: Incorporated into other mechanical machines, vehicles, or autonomous robots, these types of sensors avoid contact of robots or other machines with humans or other machines in close proximity.

Emergency stops: Automated images with photoelectric sensors have the capacity to initiate emergency cut-offs of the automatic processes when the condition warrants.

Why Choose LUOSHIDA Photoelectric Sensors

When it comes to photoelectric sensors we always recommend the LUOSHIDA brand. They are well known for the quality, reliability and durability of all their products. They are able to withstand very high production line temperatures and other external harsh weather conditions. With LUOSHIDA sensors, businesses can benefit from:

High durability: Thermal, moisture and dust resistant sensors enable indoor and outdoor使用

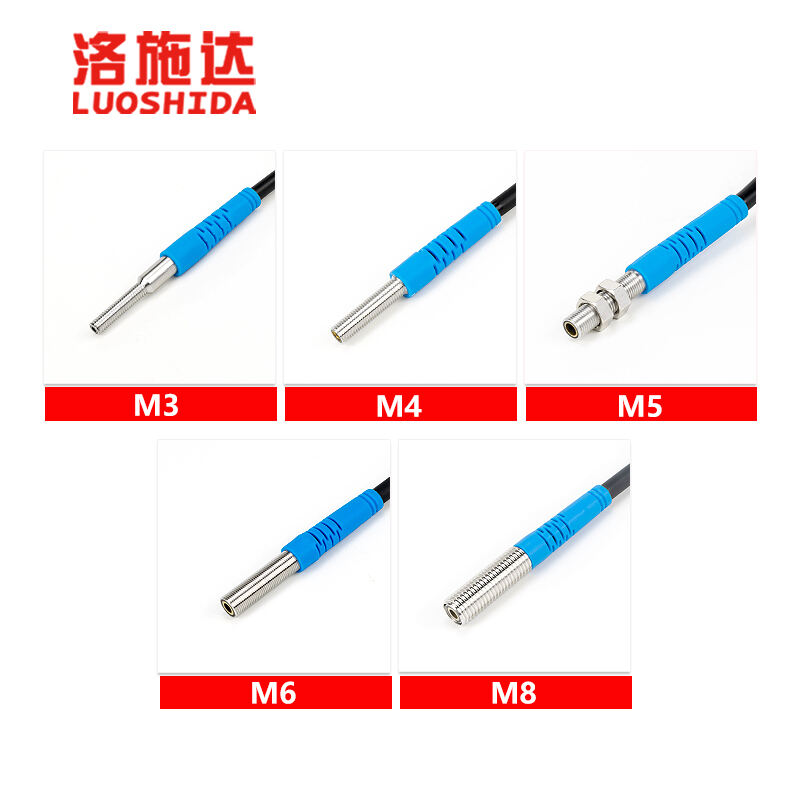

Versatility: LUOSHIDA offers an array of sensor types including through-beam, retro-reflective and ilk khaf so as to fit every individual application.

Customization options: LUOSHIDA’s solutions can be tailored to fit specific detection needs so as to maximize effectiveness.

Conclusion

Replacing industrial generators with photoelectric sensors can significantly increase efficiency as well as safety of the workspace. LUOSHIDA’s photoelectrical sensor products are sure to increase the optimization of your business as well as cut costs. The integration of these specialized sensors into your automation systems ensures an increase in productivity and reliability when it comes to your industrial processes.